More info

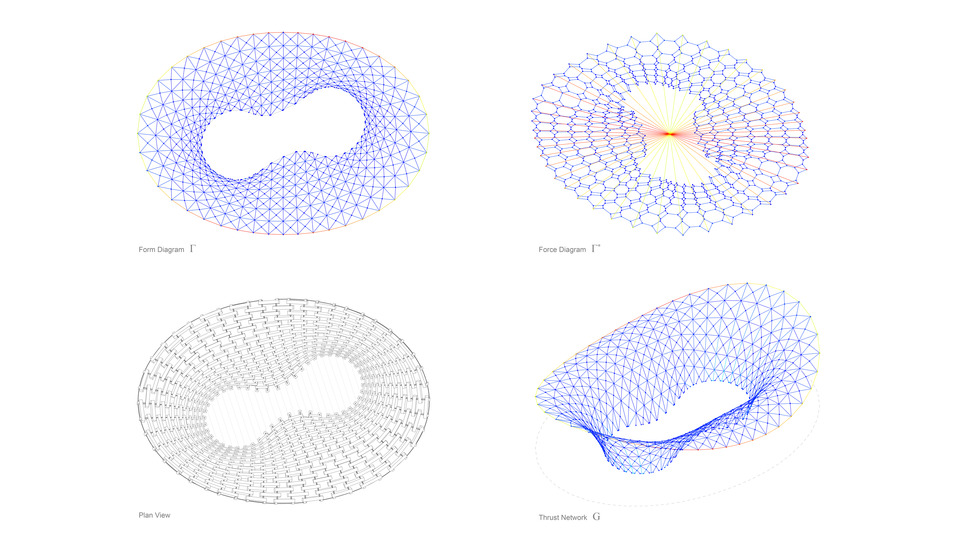

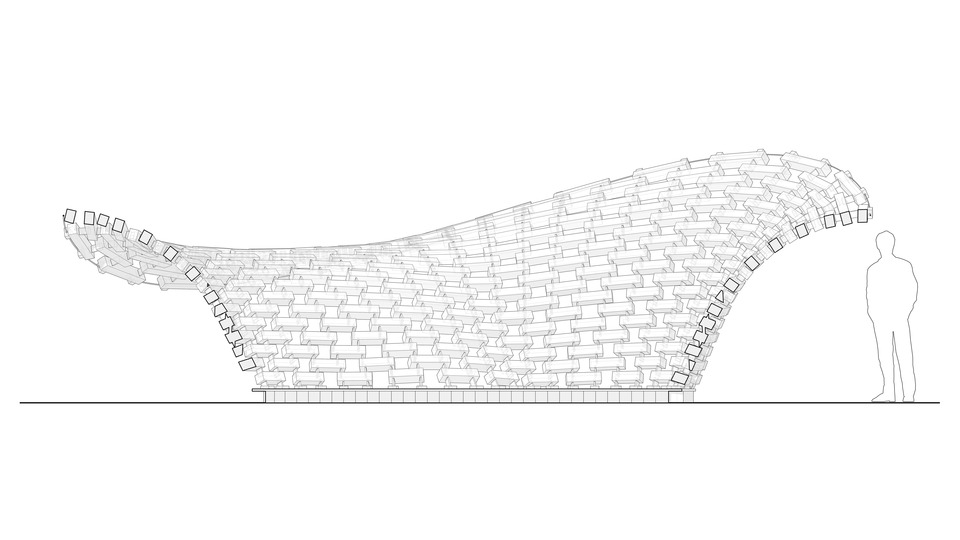

The prototype demonstrates a unique structural system that combines a compression-only surface form with a spatial tension ring. It investigates the aesthetic qualities of the concept and validates the computational results of a novel approach to form-find such shell shapes. RhinoVAULT, the form-finding plugin for Rhinoceros© developed by the Block Research Group, was used to manipulate compression and tension forces in the structural surface during the design process. The interactive design tool employs form and force diagrams to provide an intuitive and fast method, adopting the same advantages of techniques such as Graphic Statics, but extending them to three-dimensional funicular shells.

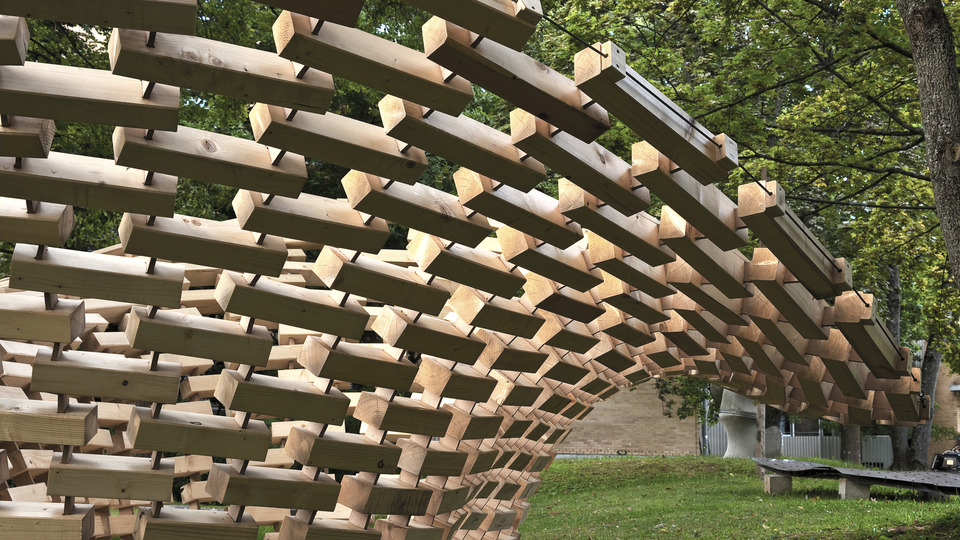

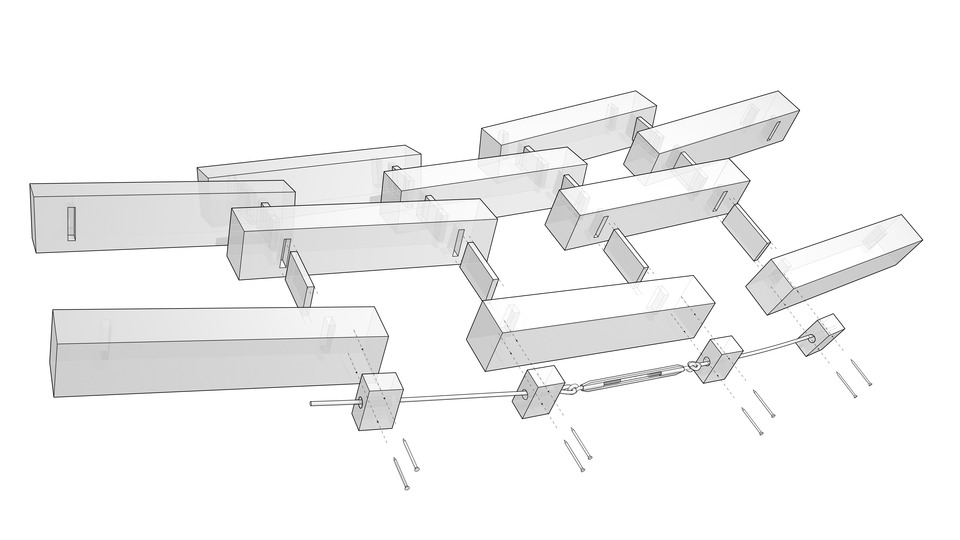

The fabrication technique simply consists of slotted timber blocks connected by straight MDF connectors. This system was developed to address the structural design requirements and fabrication constraints. The simple interlocking of blocks and connectors form the compression part of the structure, which is balanced by a steel cable as tension tie along the unsupported ridge edge. Since only self-weight is taken into account during the form finding of the shell, the structure’s material was chosen to have considerable self-weight in order to maintain stability under asymmetric loading. Moreover, the structural depth of the shell’s cross-section and the reasonably stiff connections allow for redundant force equilibria under non-uniform loading conditions. As additional safety measure, it was chosen to also glue the connectors into the blocks, hence increasing local bending resistance.

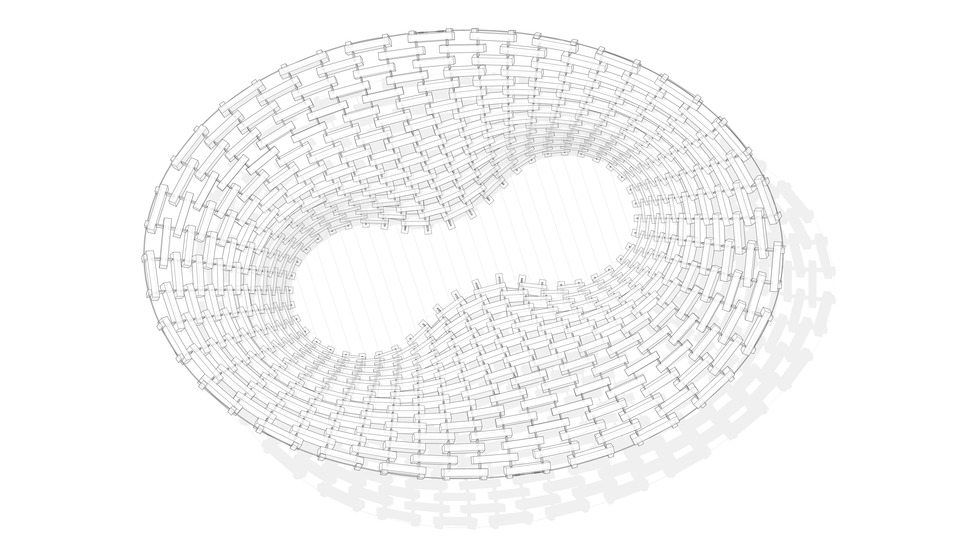

The fabrication constraints result from the use of a common 3-Axis CNC router for the production of the parts. In general, limited construction time led to a materialization strategy that did not require complex and intense fabrication, production and assembly techniques. All parts of the structure are standardized: the timber blocks have eight different lengths ranging from 25 to 60 cm; the connector pieces have seven different lengths ranging from 8.5 to 11.5 cm. The overall geometry of the structure is defined by the geometry of the CNC-milled slots. They define the angles of the four connectors per block, two on each side connecting the element to its adjacent blocks in the rows above and below. The overlap between blocks in neighbouring rows were optimized to provide sufficient distance for the milled slots from both ends of each block. This optimization process thus determined the spacing between blocks and their individual lengths.

The assembly of the structure was completed in less than two days thanks to the use of the custom CNC-machined parts, which fit together precisely. This efficient construction process obviates the need for guide- or falsework to trace and/or support the complex shape of the shell during erection.

The shape and complexity of this prototype has been determined on the size, deemed achievable within, and the available fabrication setup of the short and intense workshop. From a structural point of view, resulting shell designs can range from simple symmetric shapes to complex configurations with openings and undulating ridge edges. Independent of their complexity, all resulting shells are subject to the clear and comprehensible structural system. Funicular funnel shells represent a new typology of structurally efficient shells broadly applicable in architectural design.

Project specifications

Address

Pfaffenwaldring 14, 70569 Stuttgart, Germany

Date of completion

July 18, 2014

Surface shell

31.5 m²

Dimensions

6.6 x 4.7 x 2.2 m (l x w x h)

Total weight

623 kg (without base plate)

Materials

414 spruce timber elements (blocks) - 100 x 80 x 250-600 mm

828 MDF strips (connectors)- 60 x 15 x 85-115 mm

Team

Project Lead

- Block Research Group, ETH Zurich - Matthias Rippmann, Masoud Akbarzadeh

- Institute for Lightweight Structures and Conceptual Design (ILEK), University Stuttgart - Oliver Gericke

Scientific development and project management

- Matthias Rippmann (structural form finding and system development)

- Masoud Akbarzadeh (fabrication and system development)

- Oliver Gericke (fabrication and CNC Management)

Students

Joaquin Andres Aguilar Marquez, Tobias Becker, Florian Geiger, Sushant Goel, Vangel Kukov, Phillip Längst, Jasmin Sadegh, Guowei Wu, Roland Falk